Pottery Production at Pachacamac: The Coiling Technique

3D Models

Figures

Figure 1: Ceramic bottle produced using the press-molding technique (Donnan 1992).

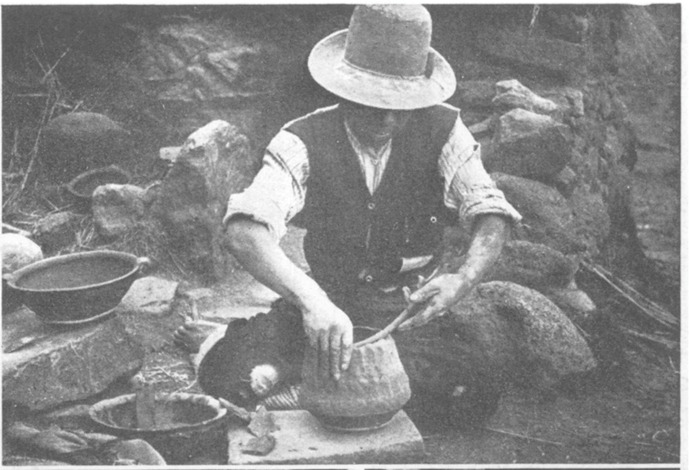

Figure 2: Raqch'i potter constructing a vessel using the coiling technique (Chávez 1984).

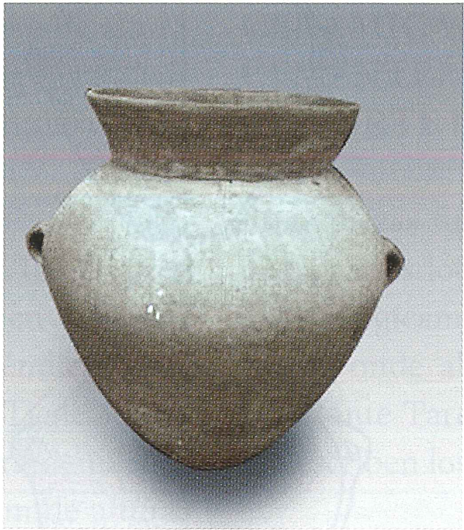

Figure 3: Photograph of an Inca raki vessel.

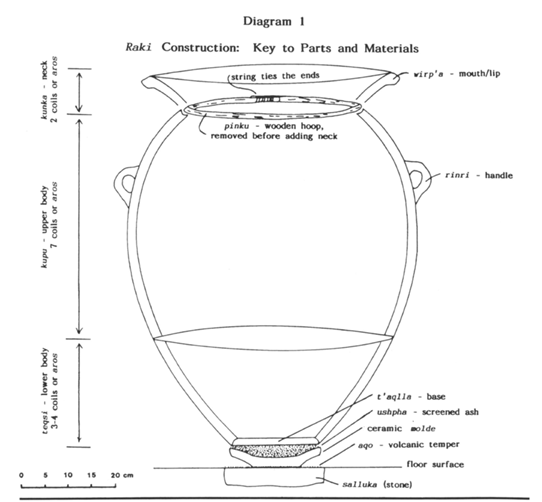

Figure 4: Raki vessel (Chávez 1984).

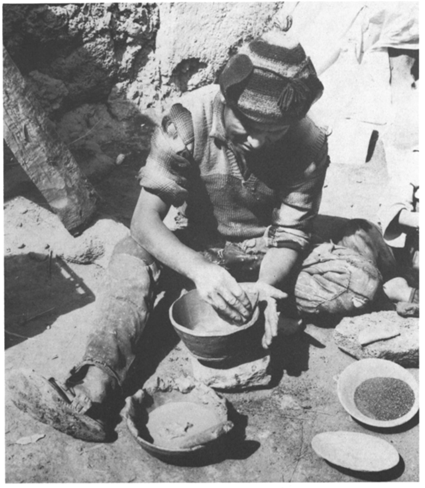

Figure 5: Raqch'i potter using a chawina to smooth a vessel's interior (Chávez 1984).

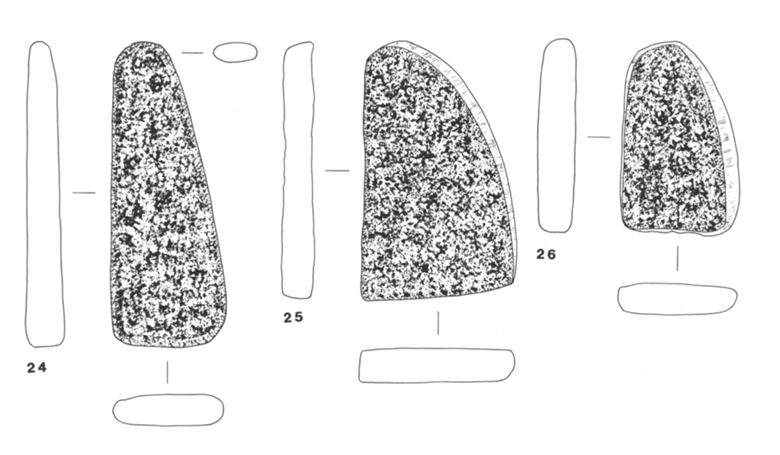

Figure 6: Teqsi chawina (left) and kupu chawina (right) (Chávez 1984).

Figure 7: Ki'suna (Chávez 1984).

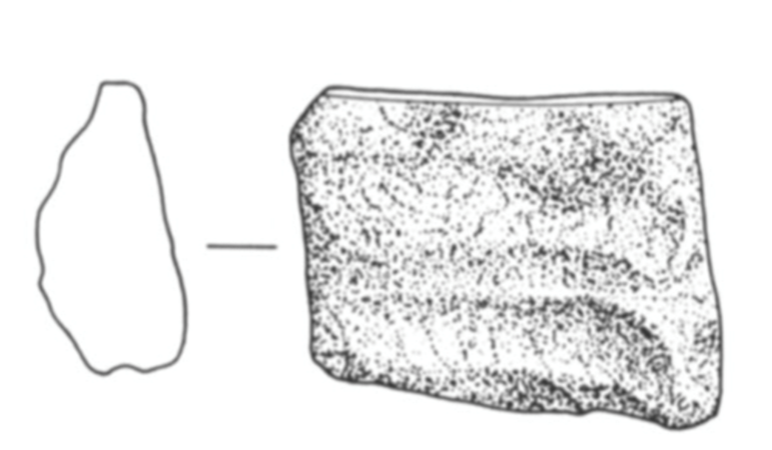

Figure 8: Qaruna (Chávez 1984).

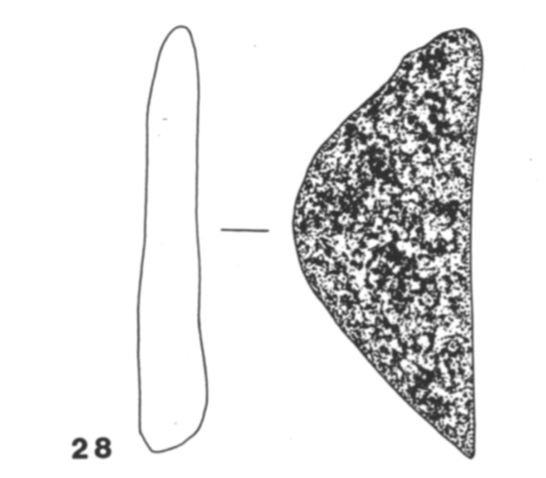

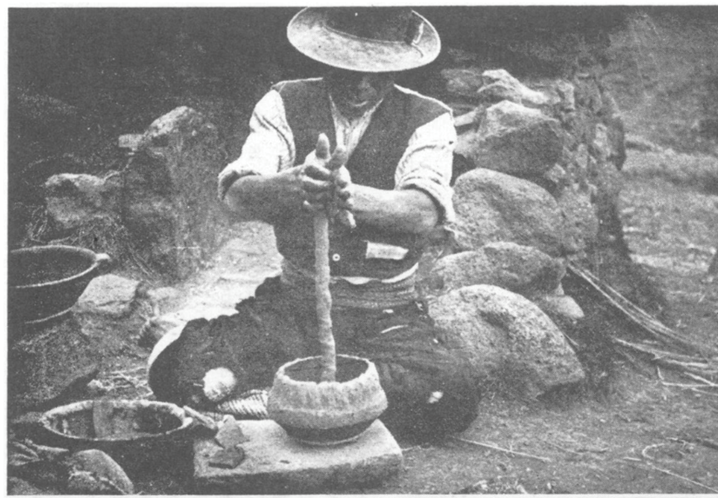

Figure 9: Llamp'uña (Chávez 1984).

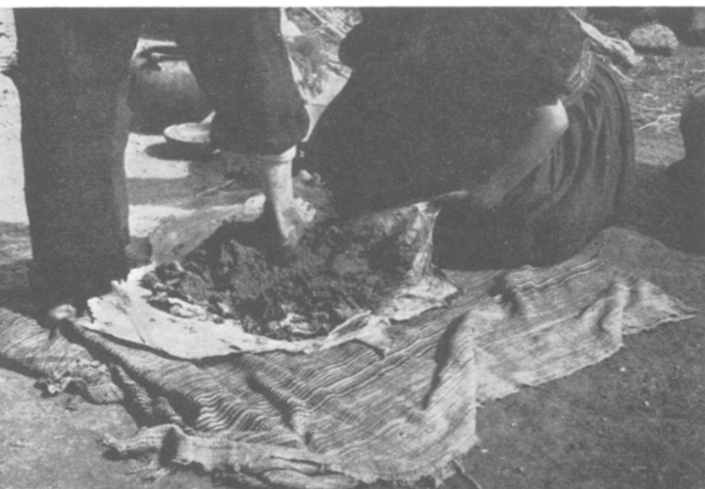

Figure 10: Aymara potter mixing clay on a piece of cloth with his feet (Tschopik 1950).

Figure 11: Raqch'i potter rolling out a coil of clay (Chávez 1984).

Figure 12: Vilcanota River.

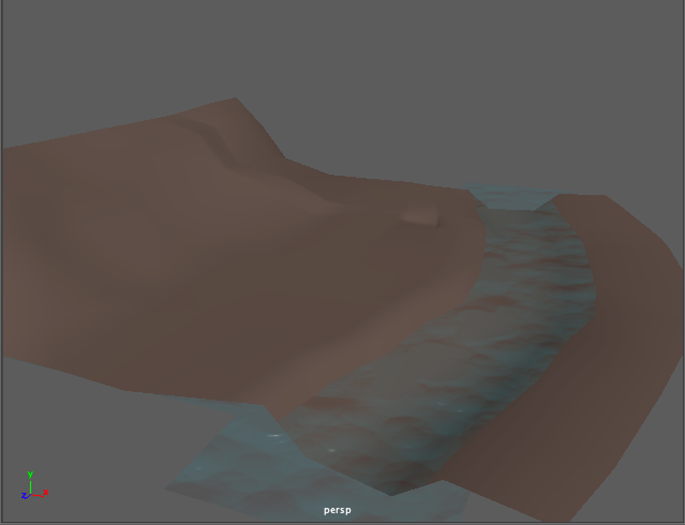

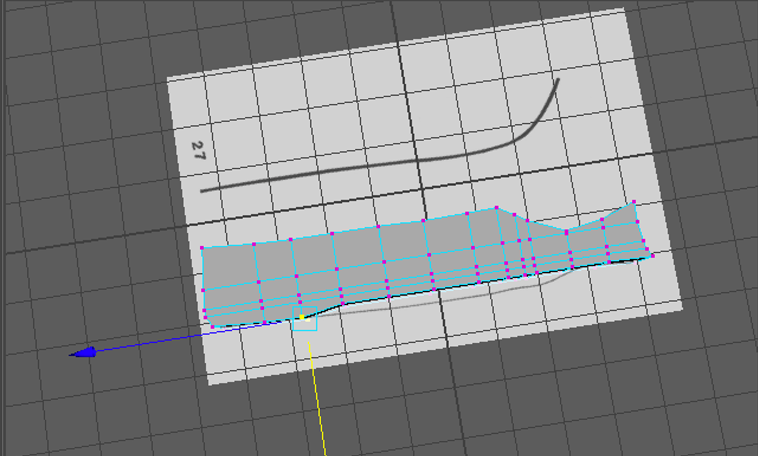

Figure 13: First attempt to construct the riverbank from where the potter harvests clay.

Figure 14: Female potter digging for clay by the river.

Figure 15: Female potter transporting clay back to her house.

Figure 16: Lurín River.

Figure 17: Male potter digging up clay from the side of a riverbank.

Figure 18: Male potter transporting clay back to his house.

Figure 19: Cowhide photograph.

Figure 20: Cowhide model after transforming vertices to match the outline provided by the reference photograph.

Figure 21: Female potter mixing the clay.

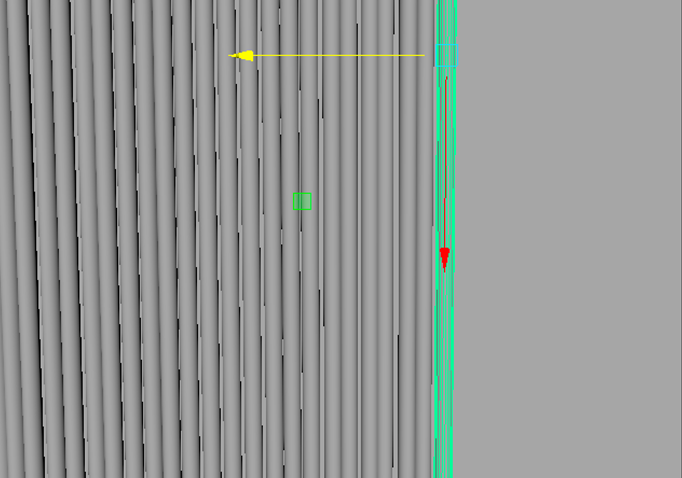

Figure 22: Constructing the reed mat.

Figure 23: Male potter mixing the clay.

Figure 24: Female potter rolling out coils.

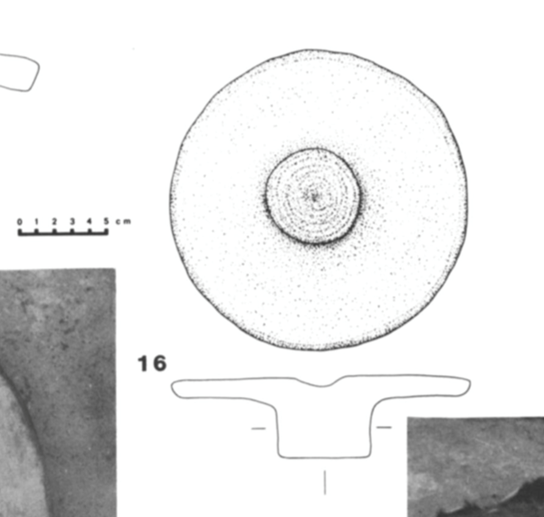

Figure 25: Female potter placing a coil to construct the teqsi.

Figure 26: Fully coiled teqsi.

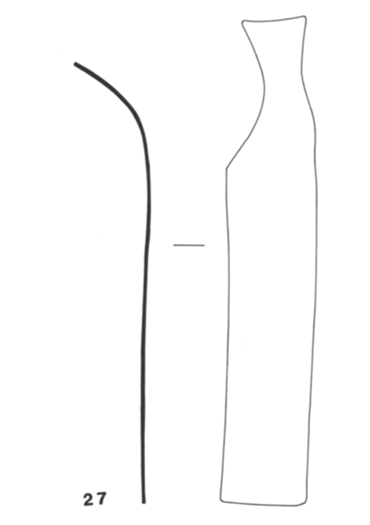

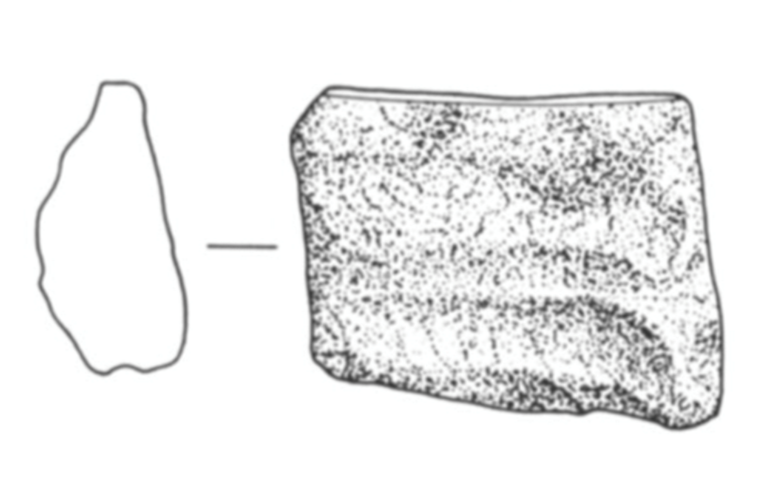

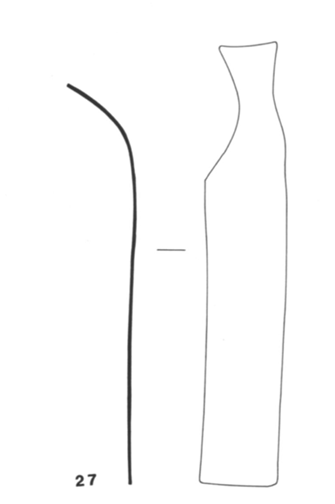

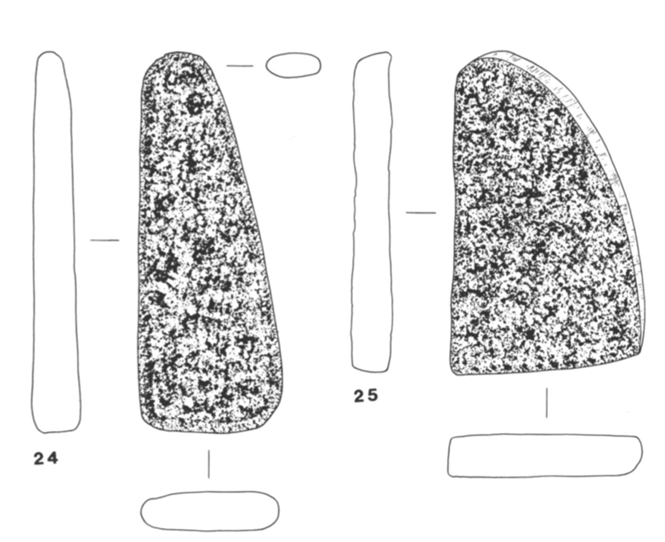

Figure 27: Ceramic plate (Chávez 1984).

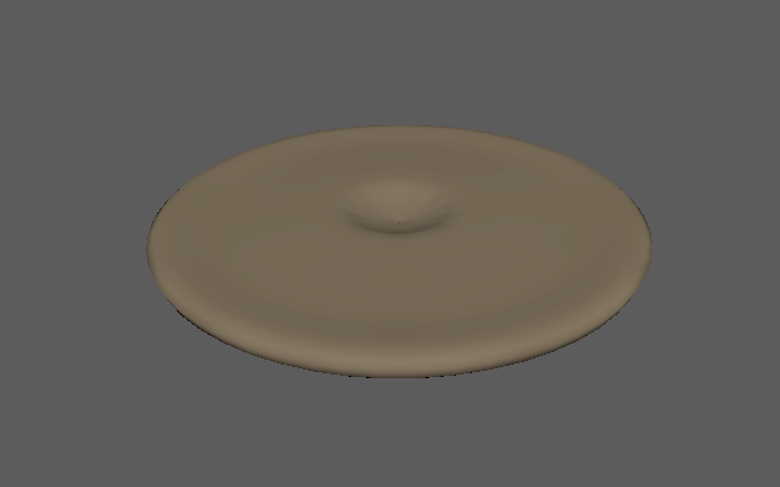

Figure 28: Modeled ceramic plate.

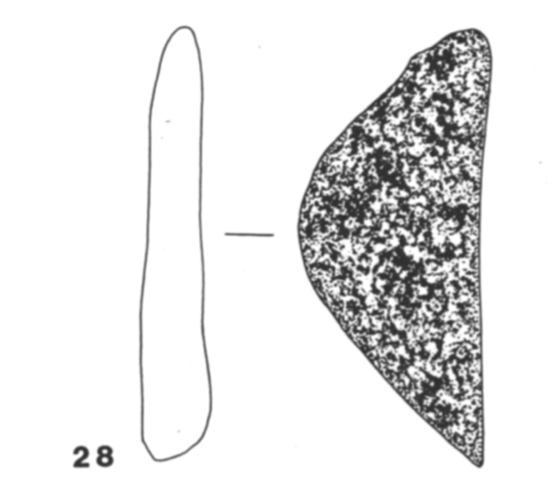

Figure 29: Llamp'uña (Chávez 1984).

Figure 30: Inverted llamp'uña.

Figure 31: Modeled llamp'uña.

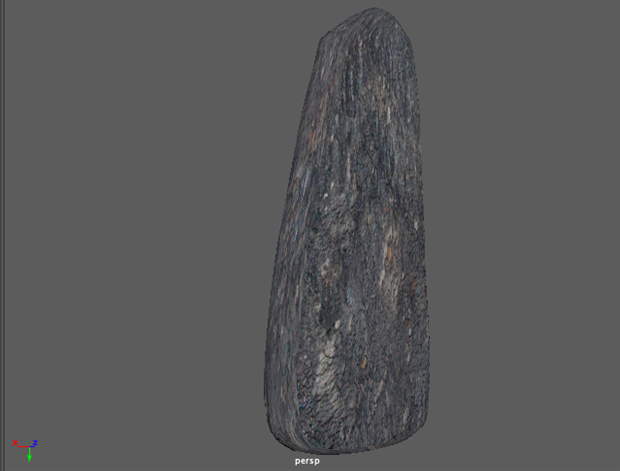

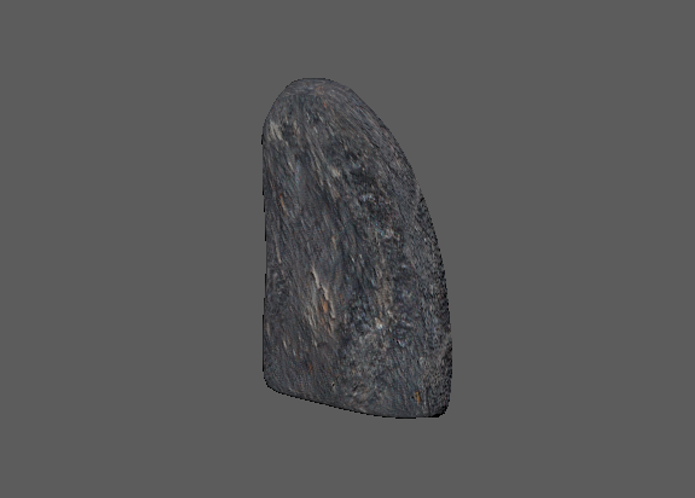

Figure 32: Qaruna (Chávez 1984).

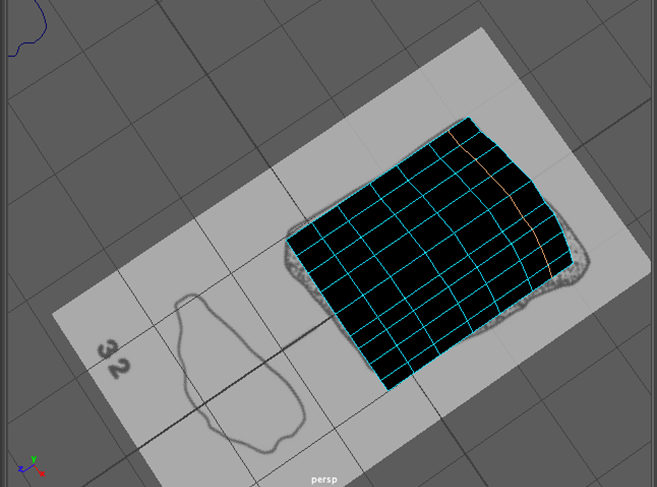

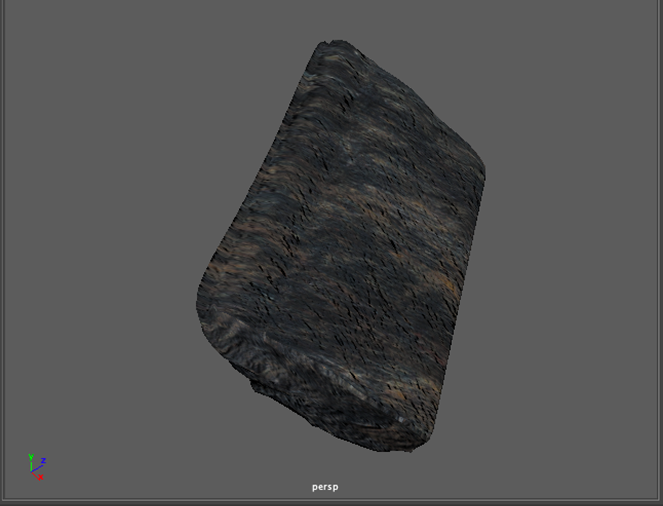

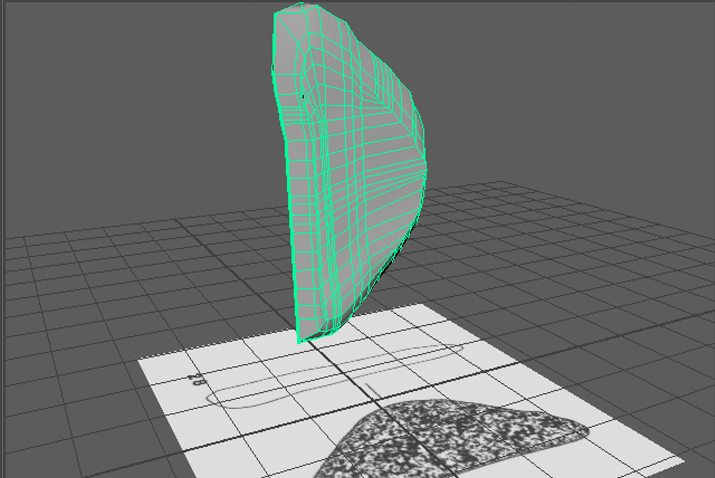

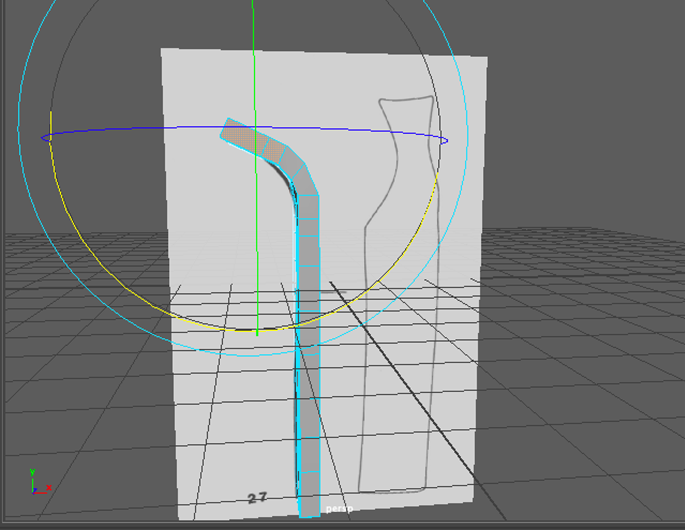

Figure 33: Constructing the qaruna by transforming vertices.

Figure 34: Modeled qaruna.

Figure 35: K'isuna (Chávez 1984).

Figure 36: Constructing the k’isuna by transforming vertices.

Figure 37: Constructing the k'isuna by rotating faces.

Figure 38: Modeled k'isuna.

Figure 39: Teqsi chawina (left) kupu chawina (right) (Chávez 1984).

Figure 40: Modeled teqsi chawina.

Figure 41: Modeled kupu chawina.

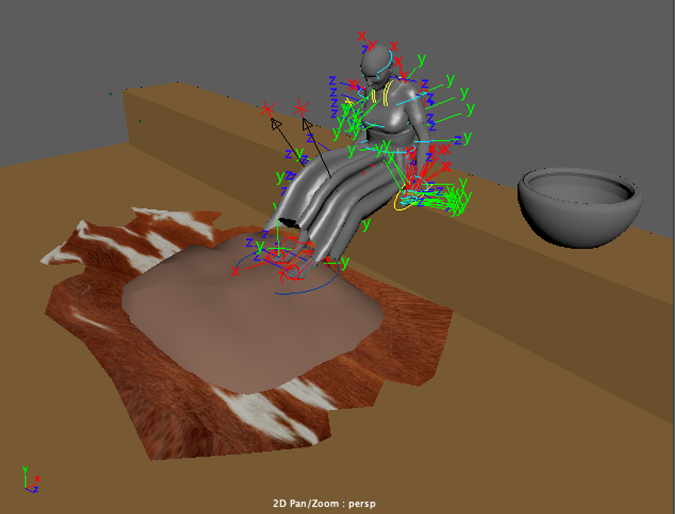

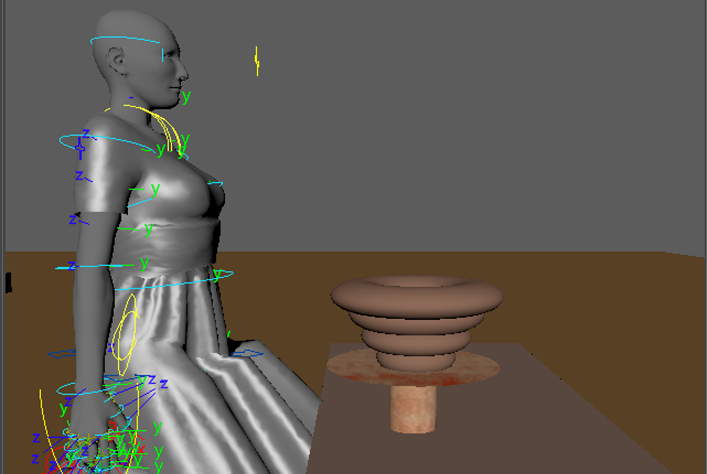

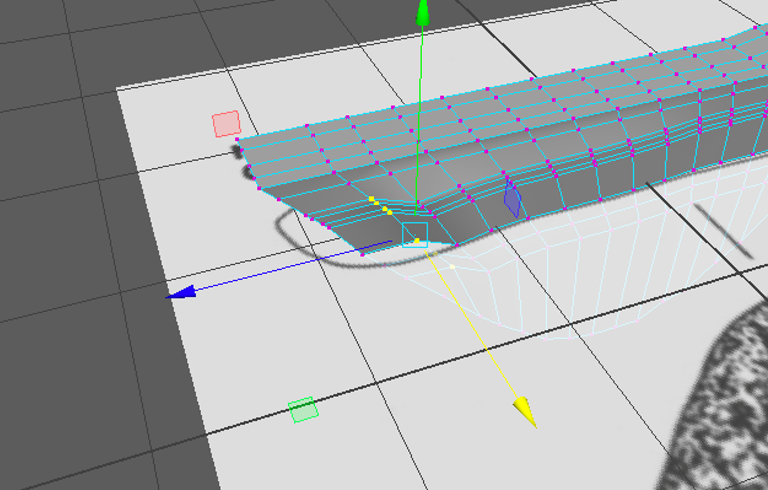

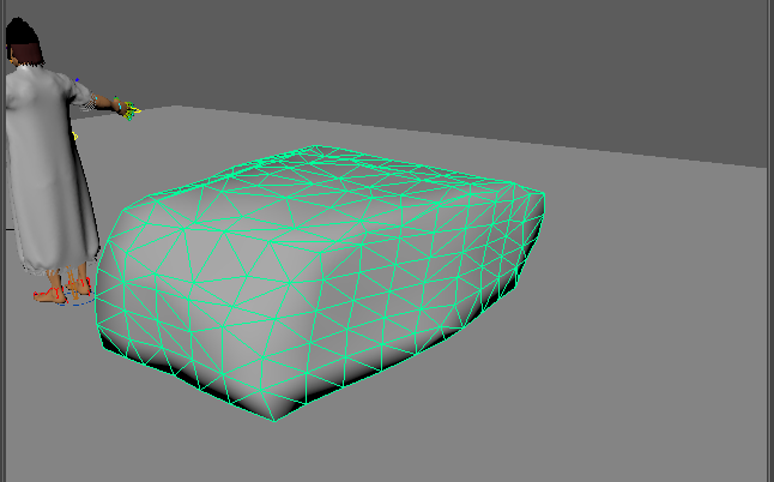

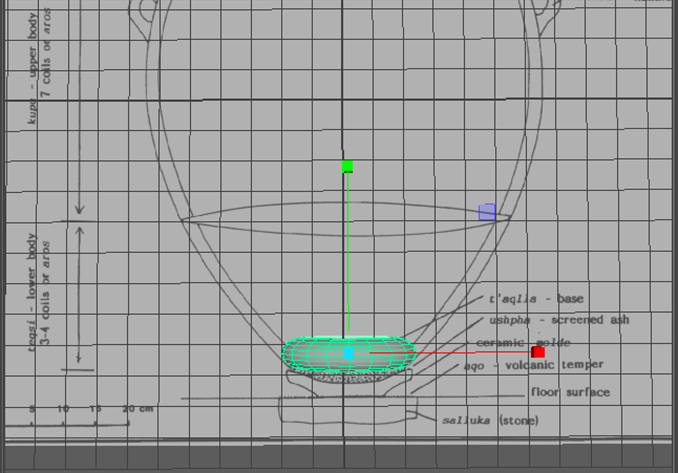

Figure 42: Modeling the background for the raki vessel construction.

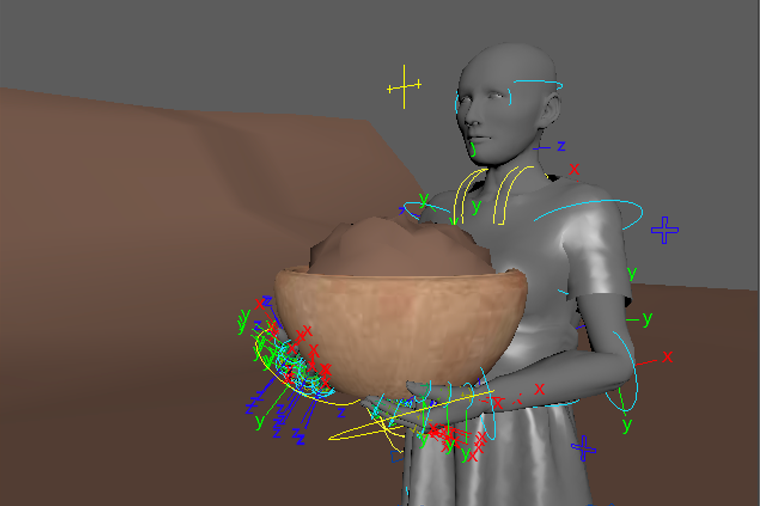

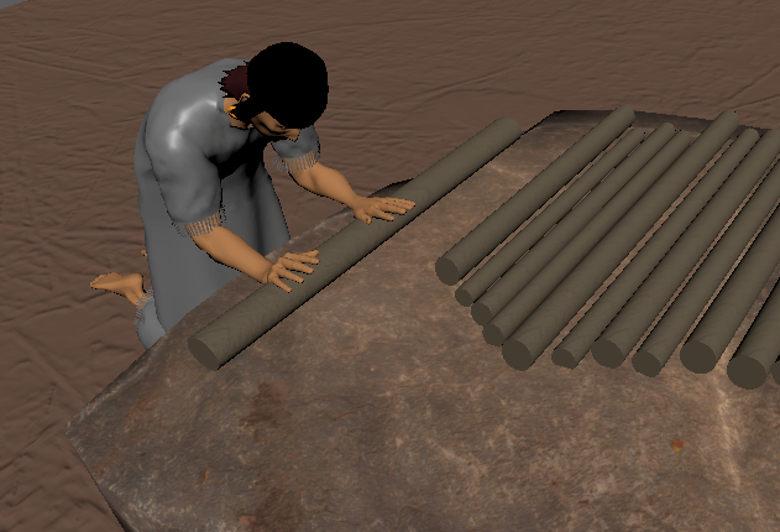

Figure 43: Male potter forming coils.

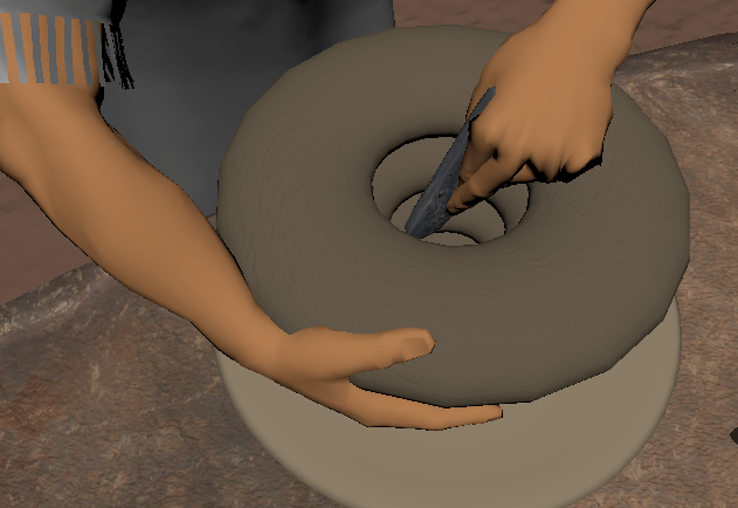

Figure 44: Constructing the teqsi.

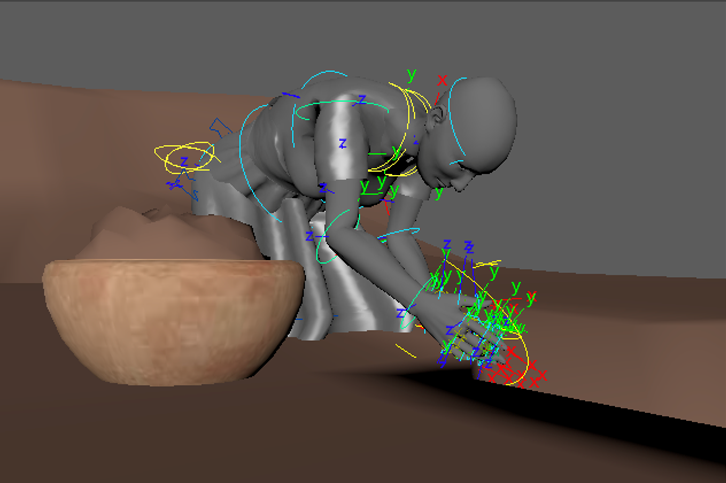

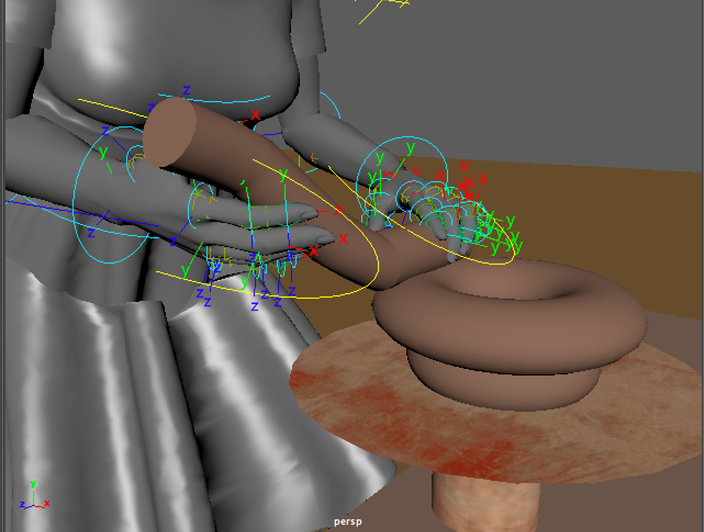

Figure 45: Male potter positioning a coil on the teqsi.

Figure 46: Fully coiled teqsi.

Figure 47: Male potter smoothing the teqsi's interior with a chawina.

Figure 48: Male potter adding coils to form a fully coiled kupu.

Figure 49: Male potter smoothing the kupu's interior with a chawina.

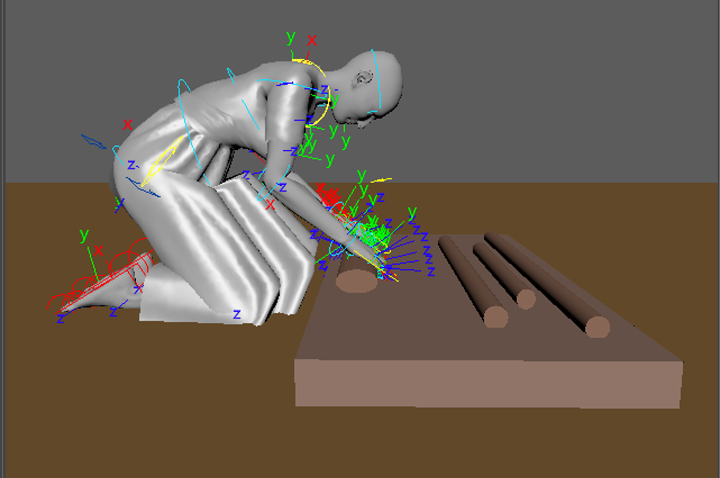

Figure 50: Male potter smoothing the raki's exterior with a k'isuna.

Figure 51: Fully smoothed raki exterior using a k'isuna.

Figure 52: Male potter smoothing the raki's exterior with a qaruna.

Figure 53: Male potter adding the neck and the handles to the raki vessel.

Figure 54: Male potter smoothing the raki's exterior with a llamp'uña.

Figure 55: Final raki vessel before firing.